Key Points

- When installing over an existing resilient floor, lay out the installation so the new seams are a minimum of 6˝ away from the original seams.

- When installing over tile floors, seams should fall in the center of the tile.

- When using tile from two or more cartons, check to be sure all pattern and lot numbers are the same for proper color match.

- Tile products with directional arrows on the back should be installed with the arrows all pointing in the same direction. Groutable, rounded edge tiles may be installed with arrows pointing in random directions.

- Do not wet wash tile for at least five days after installation. This will allow the adhesive under the tile to dry and prevent excess moisture and cleaning agents from interfering with the adhesive bond.

- Make sure tiles are butted tightly at all edges to prevent separation.

Tools

- Utility knife

- Pencil

- Medium grit sandpaper

- Sanding block

- Smooth edge trowel

- Tape measure

- Short nap paint roller

- Chalk and chalk line

- Rolling pin

- Carpenter’s square

- S-194 Patch: Underlayment & Embossing Leveler for patching or filling textured surfaces

- S-195 Underlayment Additive

- S-185 Latex Primer

Recommended Substrates

PREPARE SUBFLOOR

Inspect and prepare subfloor. Subfloor must be clean, dry, and smooth. A subfloor is the surface over which your new Armstrong Flooring tile flooring is installed.

NOTE: Do not install over particleboard, waferboard or single-layer STURD-I-FLOOR® panels, existing resilient tile floors that are below grade, existing cushioned-vinyl flooring, carpet, strip wood or plank flooring.

EXISTING VINYL FLOORING

(Only single-layer)

Must be noncushioned-backed and firmly bonded. Check for loose vinyl, gapped seams, cuts, tears, rips, or other damage. Do not install over tile below grade level.

- PREPARE

- Use a utility knife to remove loose vinyl.

- Use New Beginning Extra-Strength Floor Stripper to remove dirt and wax buildup.

- S-194 Patch, Underlayment & Embossing Leveler mixed with the S-195 Underlayment Additive to fill and level embossing on your old vinyl flooring.

- Use smooth edge trowel for applying S-194 and S-195 mixture.

- Use medium grit sandpaper and a sanding block for smoothing rough areas of S-194/S-195 mixture and/or underlayment.

PLYWOOD/PANEL TYPE UNDERLAYMENTS

If installing a new plywood subfloor, use APA Underlayment Grade. For new or existing plywood subfloors, check for loose panels, gapped joints, knots, nail holes, or other damage.

- Recommended Underlayment Panel Types:

- Plywood rated as suitable underlayment for resilient floor coverings

- Poplar or Birch Plywood with a fully sanded face and exterior glue

- Luan Plywood, Type 1 (Exterior)

- Fiber Reinforced Gypsum Underlayment, Fiber Cement Board & Cementitious Backerboard rated as suitable underlayment for resilient floor coverings

- PREPARE

- Skim Coat or S-194 Patch, Underlayment & Embossing Leveler mixed with the S-195 Underlayment Additive to smooth and fill damaged areas or textured surfaces.

- Use smooth edge trowel for applying S-194 and S-195 mixture.

- Use medium grit sandpaper and a sanding block for smoothing rough areas of S-194/S-195 mixture.

- Use S-185 Latex Primer for a superior bond.

- Use short nap paint roller for applying S-185.

CONCRETE/CERAMIC

Must be clean, dry and dust-free. Check for cracks, scaling, levelness, and other damage. Tiles can be installed over a painted concrete floor (self-stick only). If installing over ceramic tile, terrazzo, or marble, ensure that the tiles are firmly bonded.

- PREPARE

- S-194 Patch, Underlayment & Embossing Leveler mixed with the S-195 Underlayment Additive to smooth and fill damaged areas and for patching or leveling.

- Use smooth edge trowel for applying S-194 and S-195 mixture.

- Use medium grit sandpaper and a sanding block for smoothing rough areas of the underlayment.

- Use S-185 Latex Primer for a superior bond.

- Use short nap paint roller for applying S-185 Latex Primer.

Jobsite Conditions

- Resilient flooring should be stored indoors in temperatures between 30° F (-1° C) and 85° F (29° C), as long as the flooring is protected from the weather and the area is dry, out of direct sunlight and free of internal combustion.

- Condition tile in the room in which you plan to install for 48 hours. Keep room at minimum of 65° F (18° C) during that time and during installation. After installation, temperature should not fall below 65° F (18° C) for the first 48 hours, and not below 55° F (13° C) after that.

- If room is heated by radiant coils in the subfloor, the temperature of the floor surface should not exceed 85° F (29° C).

- The subfloor should be level, clean, and free of wax, grease, oil or dust.

- If necessary, patch or fill any cracks in the subfloor with Armstrong patch or latex underlayment.

- If installing over existing vinyl, use liquid underlayment or embossing leveler to smooth any texture or embossing on the old floor.

- Install over smooth, well-bonded resilient floors, ceramic, terrazzo, marble or over dry concrete and wood floors with a plywood overlay.

Plan The Layout

For more information, see: Layout and Fitting Resilient Tile

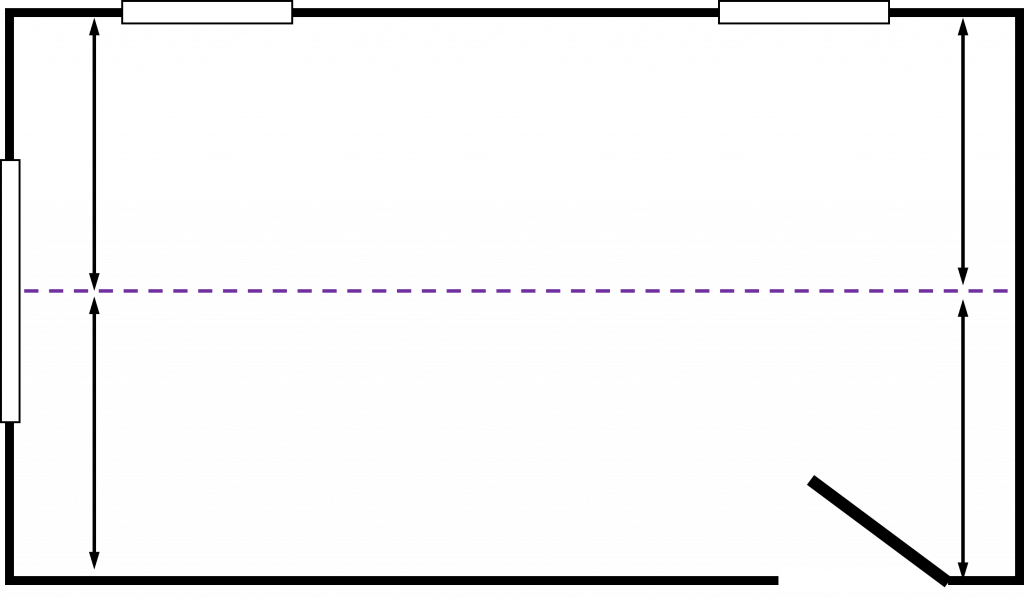

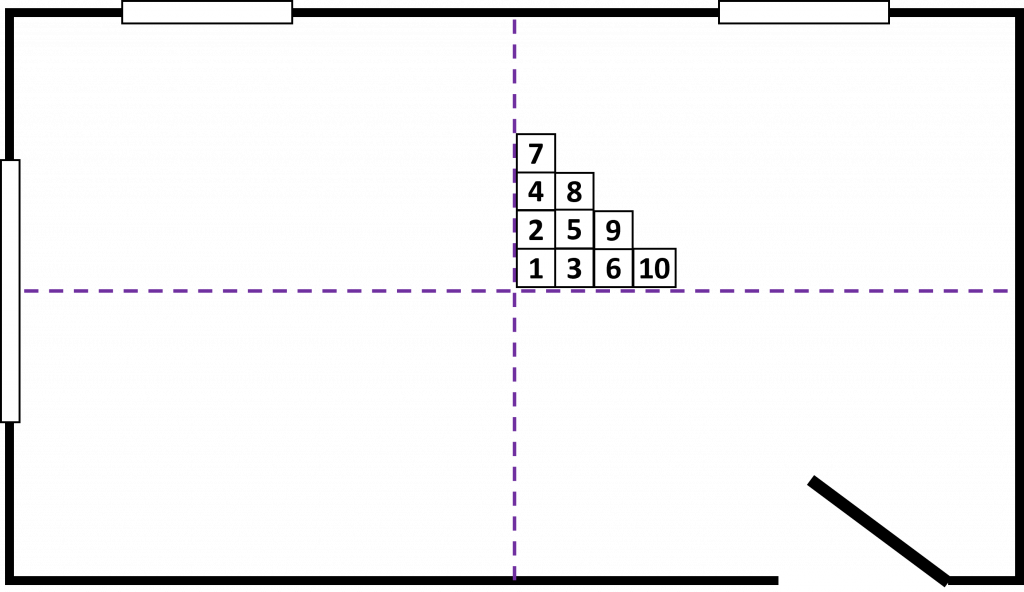

Step 1: Find the center of each of the end walls and strike a chalk line at the center of the room.

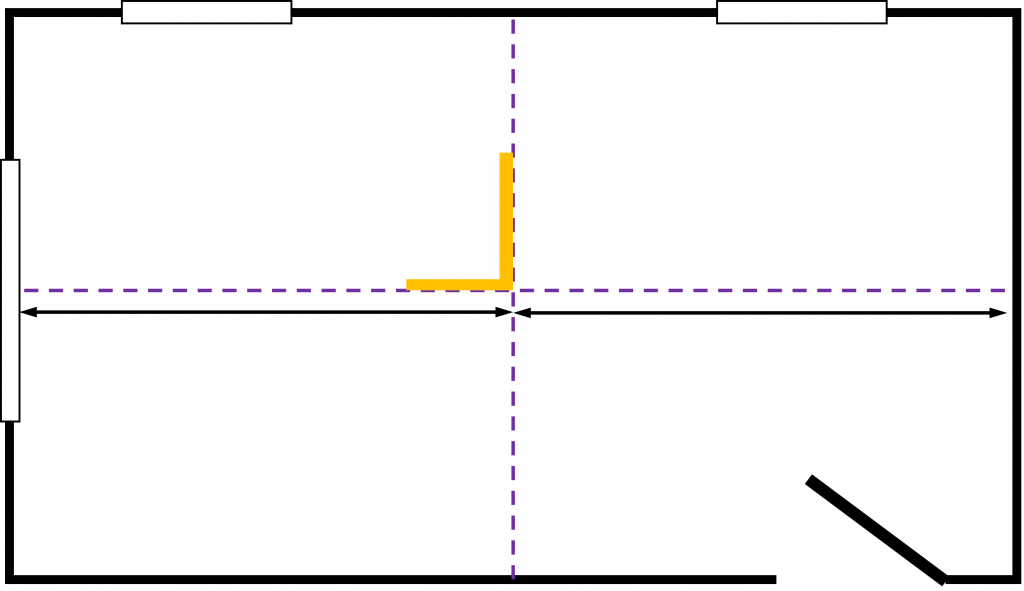

Step 2: At the midpoint of the center line, create a perpendicular line using a carpenter’s square.

Step 3: Leave release paper on back of tile, and position tiles in one quadrant of the room to determine border tile size. Shift the starting line(s) 1/2 the dimension of the tile; i.e.. shift 6″ for a 12″ tile to maximize border tile size, if necessary.

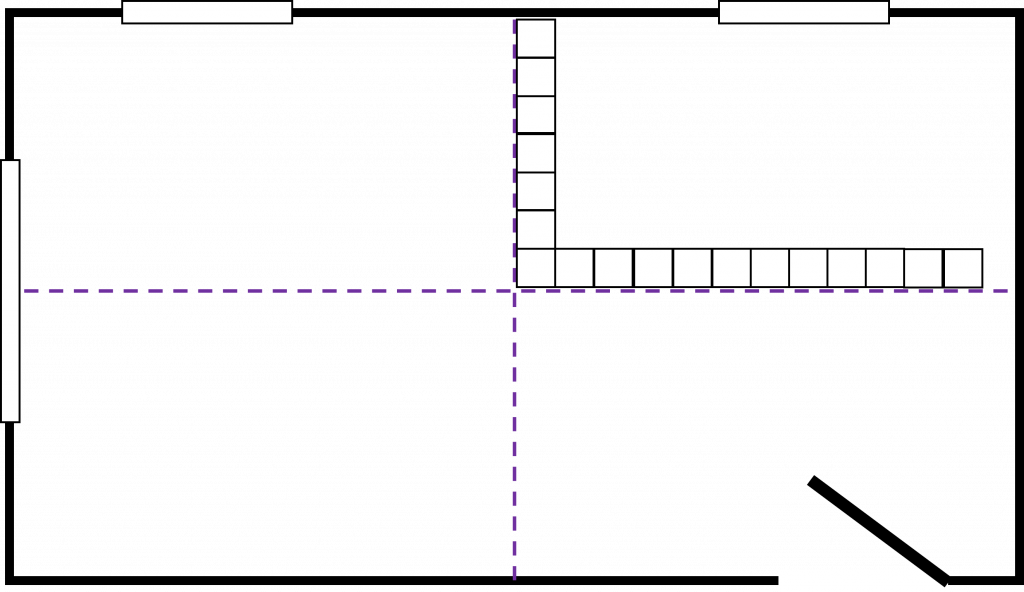

Install Tile

Step 4: Peel release paper from tile and install at intersection. Install one quadrant of tile at a time. Make sure arrows on back of all tiles point in the same direction. For rounded edge groutable tiles, arrows should be randomized. Lay tiles in pattern shown below, using chalk lines as a guide. Make sure tiles are butted tightly at all edges to prevent separation.

Cutting the border tile

Step 5: For straight cuts place a loose tile (A) face up exactly on top of the last full tile, making sure the arrows are pointed in the proper direction. Place another full tile (B) on top of tile (A) with its edge against the wall. Using tile (B) as a guide, mark the face of tile (A) with a pencil. Cut border tiles with utility knife. For irregular cuts, make a pattern and transfer it to a tile.

Finish

Step 6: Roll installed tiles in both directions to bond to floor. DO NOT wash floor for five days. Replace wall base and moldings.