Product Information

Traffic Type: Commercial

Gauge: .080″ (2.0 mm)

Roll Length: 52.49′ (15.9 m)

Roll Width: 72.1″ (183 cm)

Wear Layer: .080″ (2.0 mm)

Coverage Per Roll: 35.02 sq yd (29.28 sq m) (315.18 sq ft)

Shipping Weight: 225.08 lbs per roll (110 kg)

Rolls Per Pallet: N/A

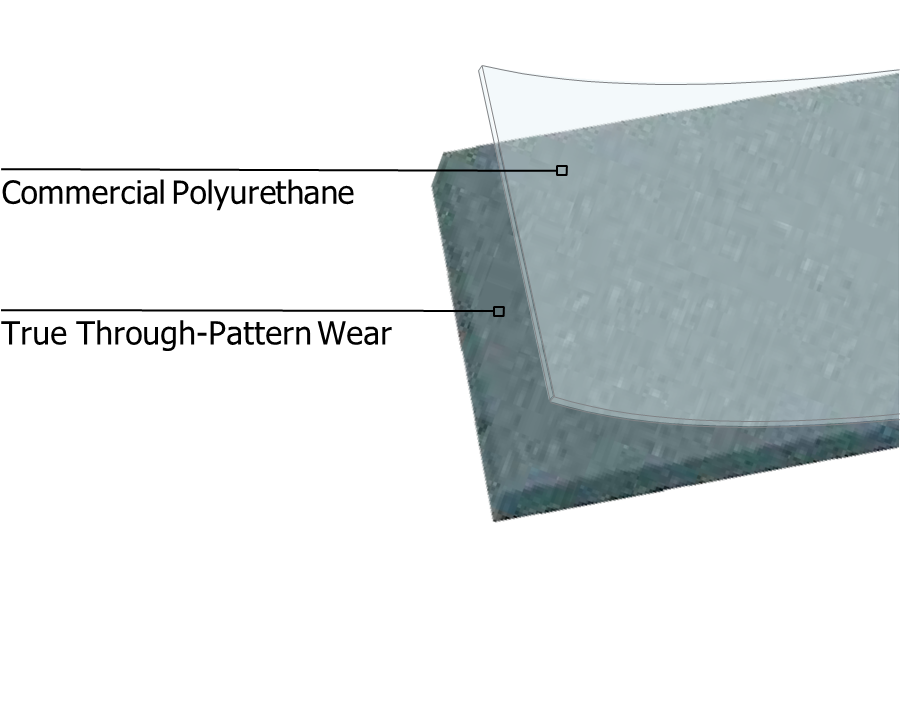

Finish: Urethane

Gloss: Low

Manufacturing Location: Australia

Warranty

10 Year Commercial Limited Warranty

Product Structure

Product Features

- See the Natralis collection at ArmstrongFlooring.com

- Proven performance in high-traffic healthcare and educational spaces

- Easy to heat weld and flash cove for spaces demanding superior infection control.

- Low maintenance – no polish required minimizes cleaning time and disruption.

- True through-pattern construction resists abrasion, scratches, and scuffs for a consistent appearance for the life of the floor.

- Withstands heavy foot and rolling load traffic.

Testing

Resistance to Staining – Commercial Resilient Flooring

Light Reflectivity Values

| Per ASTM F 1913 | |||

|---|---|---|---|

| Performance | Test Method | Requirement | Performance vs Requirement |

| Thickness | ASTM F386 | ≥ 0.075 in | Meets |

| Residual Indentation | ASTM F1914 | ≤ 0.007 in. | Meets |

| Chemical Resistance | ASTM F925 | No more than slight change in surface dulling, attack or staining | Meets |

| Resistance to Heat | ASTM F1514 | ∆E < 8 | Meets |

| Resistance to Light | ASTM F1515 | ΔE < 8 | Meets |

| Static Load Resistance @ 250* | ASTM F970 | ≤ 0.005˝ | Meets |

| Flexibility | ASTM F137 | No cracks/breaks (1.5 in. / 38 mm Mandrel) | Meets |

| Additional Testing | |||

|---|---|---|---|

| Performance | Test Method | Requirement | Performance vs Requirement |

| Fire Test Data – Flame Spread | ASTM E648 | 0.45 W/cm2 or more Class 1 | Meets |

| Fire Test Data – Smoke Evolution | ASTM E662 | 450 or less | Meets |

| Static Coefficient of Friction** | ASTM D2047/UL 410 | ≥ 0.5 | Passed |

Recommended Applications

Recommended Applications Chart – Commercial Vinyl Sheet

Guide Specification

Guide Specifications – Commercial Vinyl Sheet

Sustainability

FloorScore Certificate – Sheet Flooring

LEED and WELL for Sheet Flooring

Health Product Declarations – Sheet Flooring

Environmental Product Declarations – Sheet Flooring

SDS

Installation

Commercial Sheet Vinyl Installation Instructions

Welding Rods for Sheet Flooring

Care and Maintenance

Maintenance Recommendations:

Maintenance Recommendations For Commercial Sheet

Maintenance Products:

Cleaner: Armstrong Flooring S-485

Polish: Armstrong Flooring S-480

Product Data Table

| Natralis Model Number | Color | Weld Rod | Coordinating Wall Base |

| 70001 | White Rim | WH231 | Gray Mist |

| 70002 | Arctic | WH232 | Gray Mist |

| 70003 | Hot Springs | WN112 | Gray Mist |

| 70004 | Spray Foam | WN101 | Gray Mist |

| 70005 | Glacier Bay | WN101 | Gray Mist |

| 70006 | Birch Syrup | WH233 | Parchment |

| 70007 | Meadow | WE128 | Parchment |

| 70008 | River Rock | WH234 | Pebble |

| 70009 | Petrified Gray | WH235 | Stonewash |

| 70010 | Sand Dune | WH236 | Desert |

| 70011 | Prairie | WE117 | Desert |

| 70012 | Kenai Lagoon | WH237 | Gray Mist |

| 70013 | Waikiki | WH238 | Coastal Green |

| 70014 | Neptune Jade | WH239 | Stonewash |

| 70015 | Nugget Falls | WH240 | Gray Mist |

| 70016 | Pacific | WH241 | Almost Navy |

| 70017 | Utah | WH242 | Pebble |

| 70018 | Bryce Red | WH243 | Camel |

| 70019 | Cape Pillar | WH214 | Flax |

| 70020 | Radiant | WH244 | Essential Sand |

| 70021 | Volcano | WH245 | Warm Black |

| 70022 | Vanta | WN116 | Flagstone |

| Natralis Model Number | Color | Weld Rod | Coordinating Wall Base |